Imagine detecting hidden flaws deep within a material without causing any damage. Time of Flight Diffraction (TOFD) does just that! Developed in the 1970s, TOFD uses ultrasonic waves to detect and size internal defects with impressive accuracy. Initially used in the nuclear industry, TOFD has become a trusted NDT method across various sectors in Australia, from oil and gas to aerospace, due to its precision and efficiency.

What is Time of Flight Diffraction (TOFD)?

TOFD is an ultrasonic testing technique that detects and sizes flaws within materials by analysing the time it takes for sound waves to travel through the material and return. This technique relies on two transducers placed on either side of the inspection area: one emits sound waves, and the other receives them after they reflect or diffract off imperfections.

How Time of Flight Diffraction Works

- Transducer Setup: A transmitter and receiver are positioned on opposite sides of the material. Ultrasonic waves are sent from the transmitter, passing through the material and reflecting off any flaws back to the receiver.

- Time of Flight Measurement: The TOFD system measures the time taken for the waves to travel to and from the flaw. This “time of flight” data is crucial for calculating the location and size of the defect.

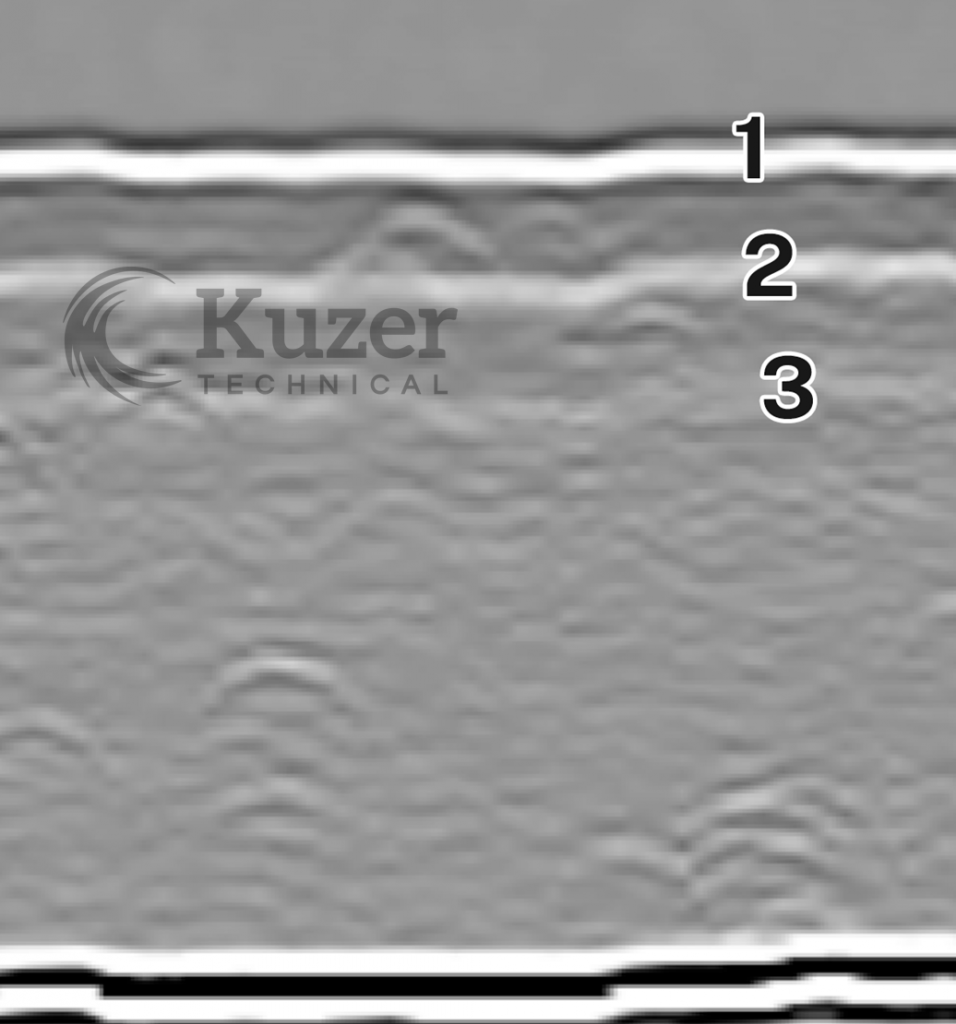

- Data Processing: Using specialised software, the data is converted into visual representations known as A-scans and B-scans. These images allow technicians to pinpoint flaws with high accuracy.

- Defect Analysis: The technician analyses the scans, identifying areas where the sound waves were disrupted. This analysis helps to determine the nature and severity of defects.

Advantages of TOFD

TOFD is valued for its accuracy, sensitivity, and ability to size defects effectively. It can detect a wide range of flaws, such as cracks, voids, and inclusions, within welds or other critical components. Compared to radiography, TOFD provides higher detectability and characterisation for subsurface flaws, making it ideal for safety-critical inspections.

Limitations to Consider

While TOFD is highly effective, it does have some limitations. For example, it may struggle with near-surface defects due to the presence of dead zones, and rough surface conditions can impact wave propagation. It is also less effective on materials with high attenuation, such as certain alloys.

If you’re interested in TOFD or other NDT techniques, get in touch to learn about training options and how to master these advanced methods! Contact us