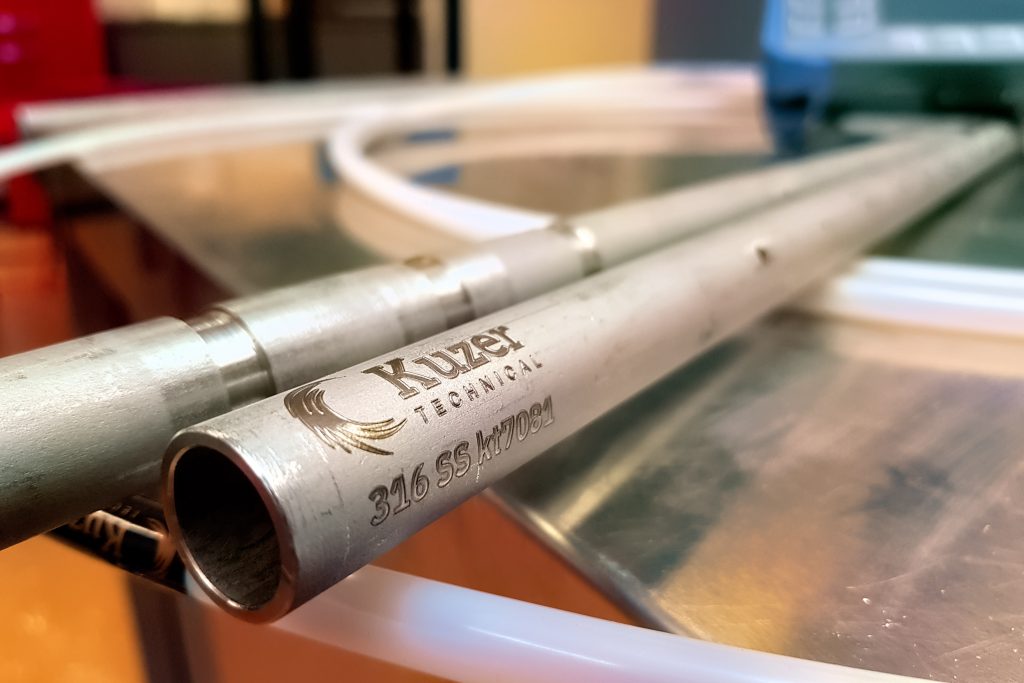

Imagine holding a coil of wire. As you pass an alternating current through it, a magnetic field forms, circling the coil like invisible loops. Now, bring a conductor—such as a piece of aluminium—close to this magnetic field. Something fascinating happens: eddy currents, swirling electric currents, begin to flow within the metal. These currents act like tiny detectives, tracing out imperfections hidden beneath the surface.

Eddy Current Testing (ET) is a non-destructive testing method that leverages this phenomenon. By observing changes in these currents, ET can reveal cracks, variations in thickness, and alterations in material properties without causing any damage to the object being examined.

How Does Eddy Current Testing Work?

- Inducing Eddy Currents:

- When you move the coil near a conductive material, the alternating magnetic field induces eddy currents within that material.

- Detecting Flaws:

- If there’s a flaw, such as a crack, the eddy currents must divert around it, leading to changes in the magnetic field.

- These changes are detected by the coil, similar to how ripples in a pond are altered when they encounter an obstacle.

- Interpreting the Data:

- By analyzing these changes, an eddy current tester can “see” beneath the metal’s surface, identifying imperfections that are not visible to the naked eye.

The Marvels of Eddy Current Testing

Eddy Current Testing is highly valued for its precision and versatility. Here are some of its key advantages:

- Instant Results:

- Once set up, an ET system provides immediate feedback, allowing for quick decision-making.

- Minimal Preparation:

- The tested part typically requires no special cleaning or preparation, streamlining the inspection process.

- Safety:

- ET does not involve harmful radiation or chemicals, making it safe for both operators and the environment.

- Versatility:

- It can be used on a variety of conductive materials and for different types of inspections.

However, there are some limitations to consider:

- Material Restriction:

- ET only works on conductive materials, limiting its applicability to non-conductive substances.

- Orientation Sensitivity:

- Detecting defects parallel to the surface can be challenging, potentially requiring complementary testing methods.

Beyond Defect Detection

Eddy Current Testing isn’t just for finding flaws. It can also:

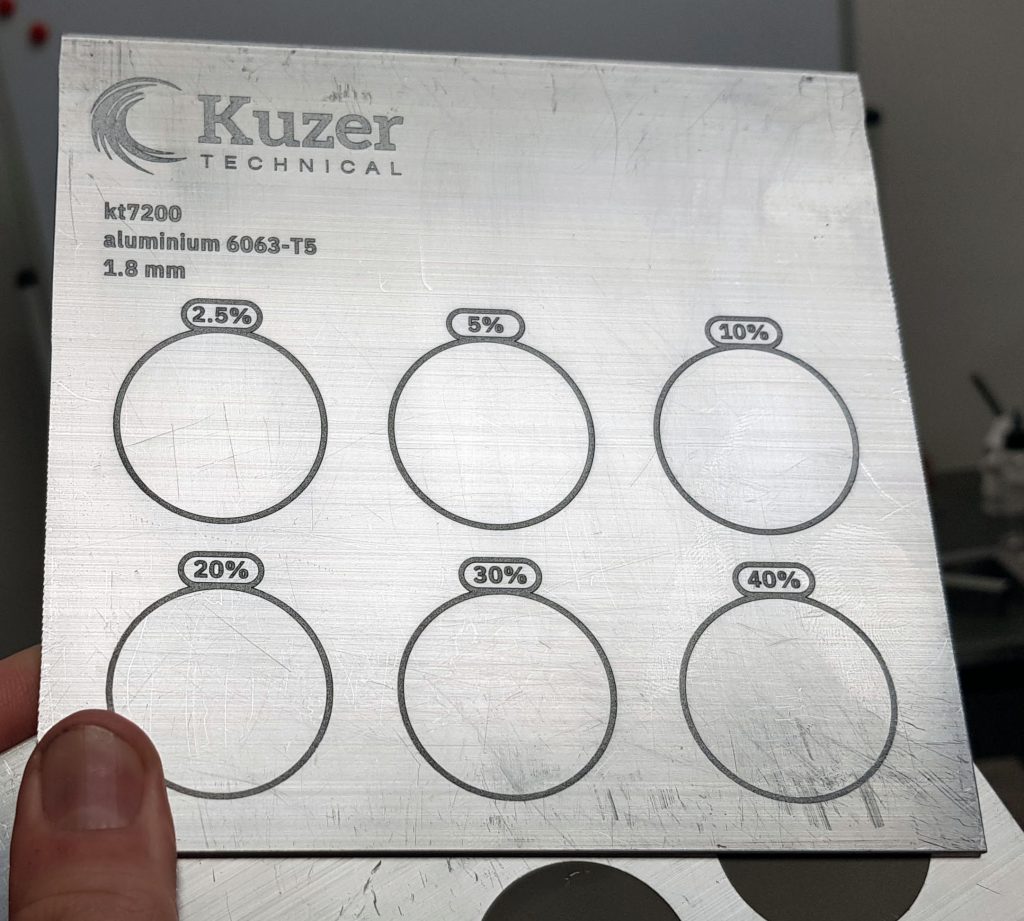

- Measure Material Thickness:

- ET can accurately determine the thickness of a material, which is crucial in industries where precise measurements are essential.

- Assess Material Properties:

- It can identify whether a material has been heat-treated or if its properties have changed, similar to discerning if a chocolate bar contains caramel just by holding it near a magnet.

In Summary

Eddy Current Testing is a remarkable technique that combines simplicity with sophistication. It allows us to:

- Peek Inside Metals:

- Inspect the internal structure without any invasive procedures.

- Find Hidden Flaws:

- Ensure the integrity and safety of materials by detecting imperfections that aren’t visible externally.

- Ensure Safety and Quality:

- Maintain high standards in manufacturing, construction, and various other industries by providing reliable and immediate inspection results.

All of this is achieved without leaving any mark on the tested object, making Eddy Current Testing an indispensable tool in modern non-destructive evaluation.

Visualizing Eddy Current Testing

To better understand ET, think of it like this:

- Coil and Magnetic Field:

- The coil generates a magnetic field that penetrates the conductive material.

- Eddy Currents as Detectives:

- These currents flow within the material, responding to its internal structure.

- Flaw Detection as Obstacle Navigation:

- Just as ripples in a pond change when they hit a stone, eddy currents alter their path when encountering a flaw, signaling its presence.

By mastering Eddy Current Testing, you gain a powerful method to ensure the quality and safety of materials and structures in various applications, from aerospace to manufacturing.

Get in contact with us today to explore more learning options and courses: Contact us