Colour Blindness in Non-Destructive Testing

Colour vision deficiency, commonly known as colour blindness, affects approximately 8% of males and 0.5% of females worldwide. In Non-Destructive Testing (NDT), where colour discrimination can be crucial, this condition presents unique challenges. However, colour blindness doesn’t necessarily disqualify individuals from the profession. This guide explores the impact of colour blindness on NDT, discusses opportunities for affected individuals, and provides a protocol for assessing its impact on work performance.

Understanding Colour Blindness in NDT

Colour vision plays a significant role in many NDT techniques, particularly in:

- Colour contrast penetrant testing (PT)

- Fluorescent magnetic particle testing (MT)

- Visual inspection of welds and other components

The impact of colour blindness can vary depending on the specific type and severity of the condition, as well as the particular NDT method being used.

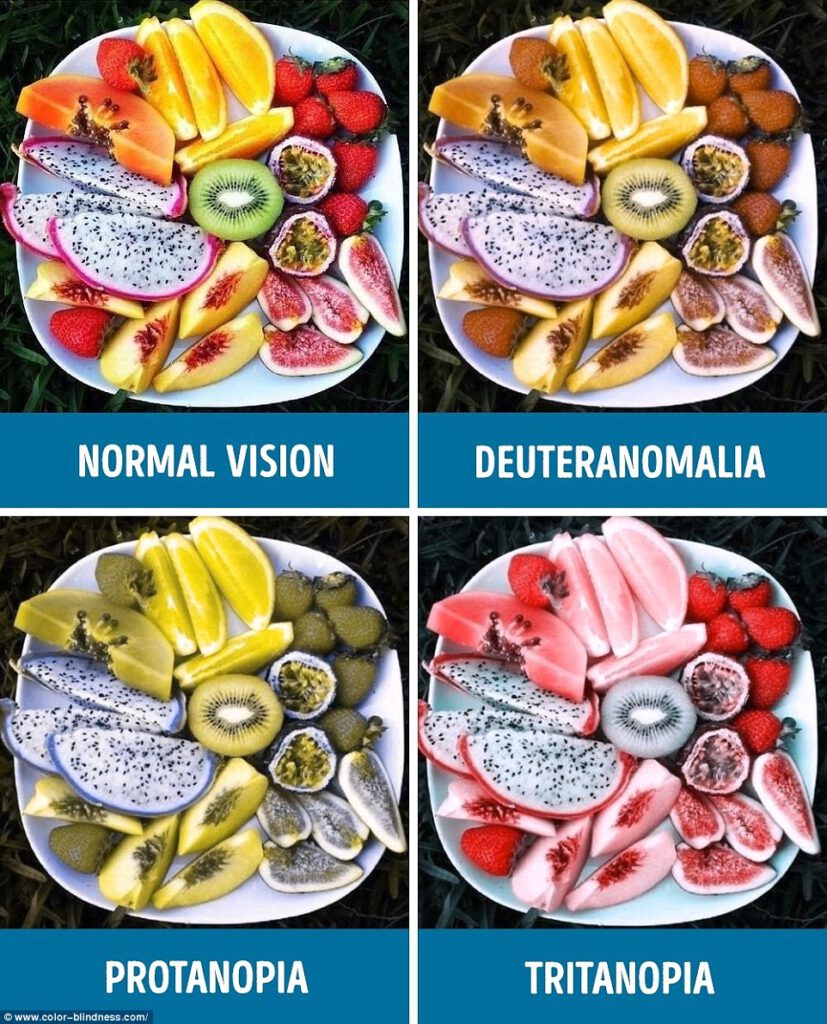

Colour vision deficiency encompasses several types, each affecting colour perception differently:

- Protanopia: This type involves an inability to perceive red light, resulting in reds appearing as beige or grey, and greens may seem more yellow. In NDT, this can affect tasks like colour contrast penetrant testing, where red dyes are commonly used.

- Deuteranopia: This is the most common type, characterized by difficulty distinguishing between red and green hues. Red and green can appear very similar, which poses challenges in NDT methods that rely on these colours for identifying defects.

- Tritanopia: This rare form affects blue and yellow perception. Blues may appear greener, and it may be challenging to distinguish between blue and yellow. While less common, it can still impact NDT tasks that use these colour contrasts.

Industry Standards and Accommodations

ISO 9712, the standard for qualification and certification of NDT personnel, acknowledges the importance of colour vision in NDT. While the ability to distinguish colours or shades of grey is essential, the standard allows for accommodations based on specific job requirements.

Challenges and Opportunities in Different NDT Techniques

Fluorescent Techniques: A Bright Spot

Fluorescent NDT techniques, such as fluorescent MT and some PT methods, present unique opportunities for those with colour vision deficiencies:

- High Contrast: These methods use particles or dyes that glow bright yellow-green under ultraviolet (UV) light, creating high-contrast indications against a dark background.

- Colourblind-Friendly: Most forms of colour blindness, including the common red-green type, should not significantly impact the ability to perform these tests.

- Research Gap: There’s been limited research specifically addressing colourblindness in fluorescent NDT, indicating a potential area for future study.

Colour blindness does not greatly affect any flouro methods, because the detection of the indications is more a matter of luminance detection and not colour distinction. Luminance detection is handled by the shades of gray assessment and not colour assessment.

Colour Contrast Penetrant Testing: Challenges and Solutions

Colour contrast PT is the method most affected by red-green colour blindness because the red can’t be contrasted against the gray/white background properly. If this scenario is a concern, a mitigation can be increasing the sensitivity by using fluorescent techniques.

BINDT offers a guidance document on assessing visual acuity, but leaves it to the employer for how to navigate any colour deficiencies with their staff. PL/44 document: https://www.bindt.org/downloads/PSL44.pdf

Assessment Protocol: Determining the Impact of Colour Blindness on NDT Work

For NDT professionals, assessing how a technician’s colour blindness affects their work requires a systematic approach. Here’s a concise protocol:

Initial Screening

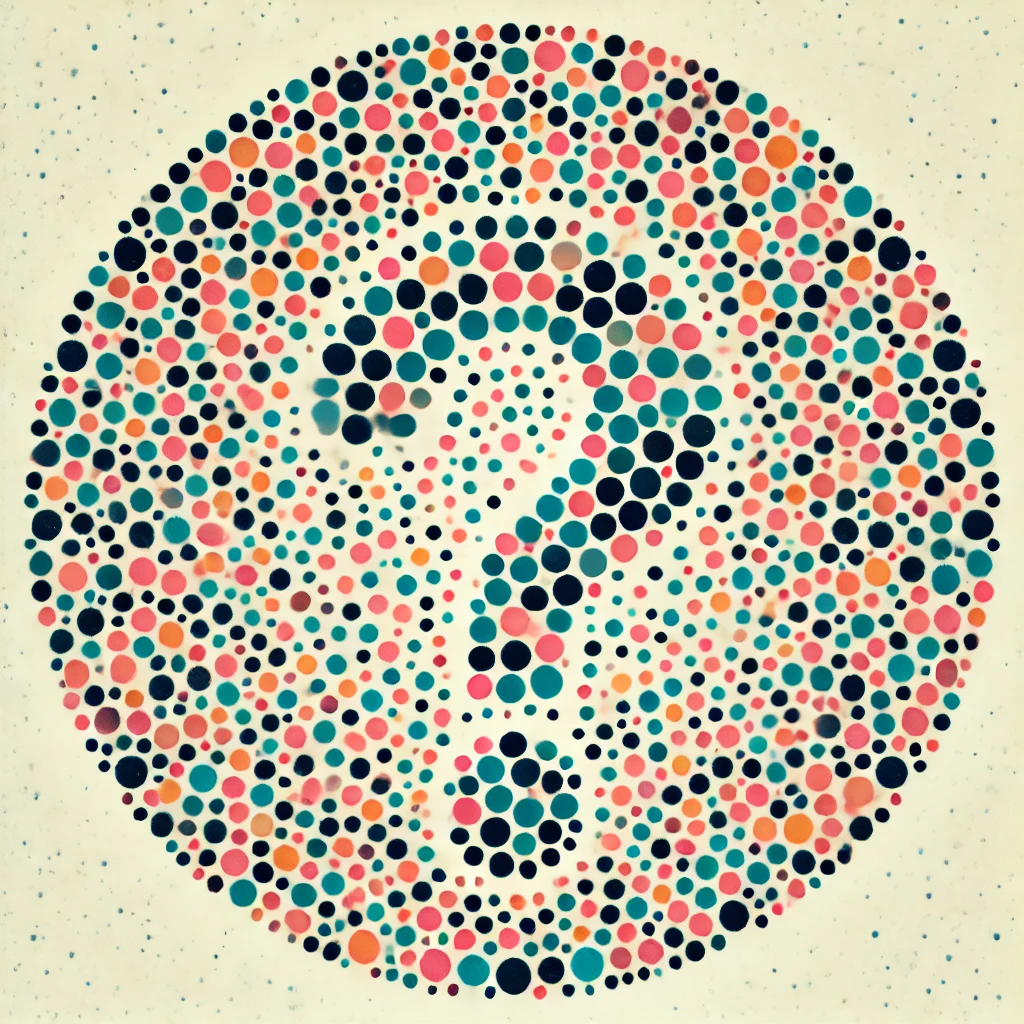

- Conduct standardized colour vision tests (e.g., Ishihara, Farnsworth-Munsell 100 Hue)

- Document the type and severity of colour blindness

Task Analysis and Controlled Testing

- Identify colour-critical elements in each NDT task

- Set up controlled tests mimicking real-world NDT scenarios

- Compare the technician’s performance to established standards

On-the-Job Observation and Performance Metrics

- Observe the technician performing actual NDT tasks

- Track detection rates, false positives, and time taken for colour-dependent tasks

Technician Self-Assessment and Accommodation Testing

- Encourage open communication about challenging situations

- Trial and assess potential accommodations (e.g., enhanced lighting, colour-correcting glasses)

Method-Specific Evaluation

- Assess performance in colour contrast PT, fluorescent methods, and visual inspections

- Use digital image analysis tools for objective measurement when possible

Ongoing Management

- Schedule periodic re-evaluations

- Consult specialists for complex cases

- Maintain thorough documentation compliant with privacy laws and company policies

This assessment should be conducted respectfully, prioritizing the technician’s dignity and adhering to relevant employment laws and regulations.

Conclusion

While colour vision deficiency presents challenges in some aspects of NDT, it doesn’t preclude a successful career in this field. With appropriate support, accommodations, and focus on strengths, individuals with colour blindness can thrive in various NDT roles.

Understanding your visual capabilities is crucial for your NDT career. We offer comprehensive visual acuity assessments, including colour vision testing, for all students on our NDT courses.

Contact us to schedule your assessment!